Construction activities heavily rely on a robust inventory system, as over 50% – 60% of the construction expenditure is met by the material management process. The need for an inventory management system exceeds far beyond just meeting the daily needs of construction activities and acts as a backup resource in times of uncertainty like the Covid pandemic on hand. Having a sound inventory in place is vital for the smooth and uninterrupted work-flow as no work shall be completed on time without the optimal utility of the construction inventory system.

This article is about Tactive’s real-time solution to simplify the complex task of managing the inventory, while also increasing the overall productivity.

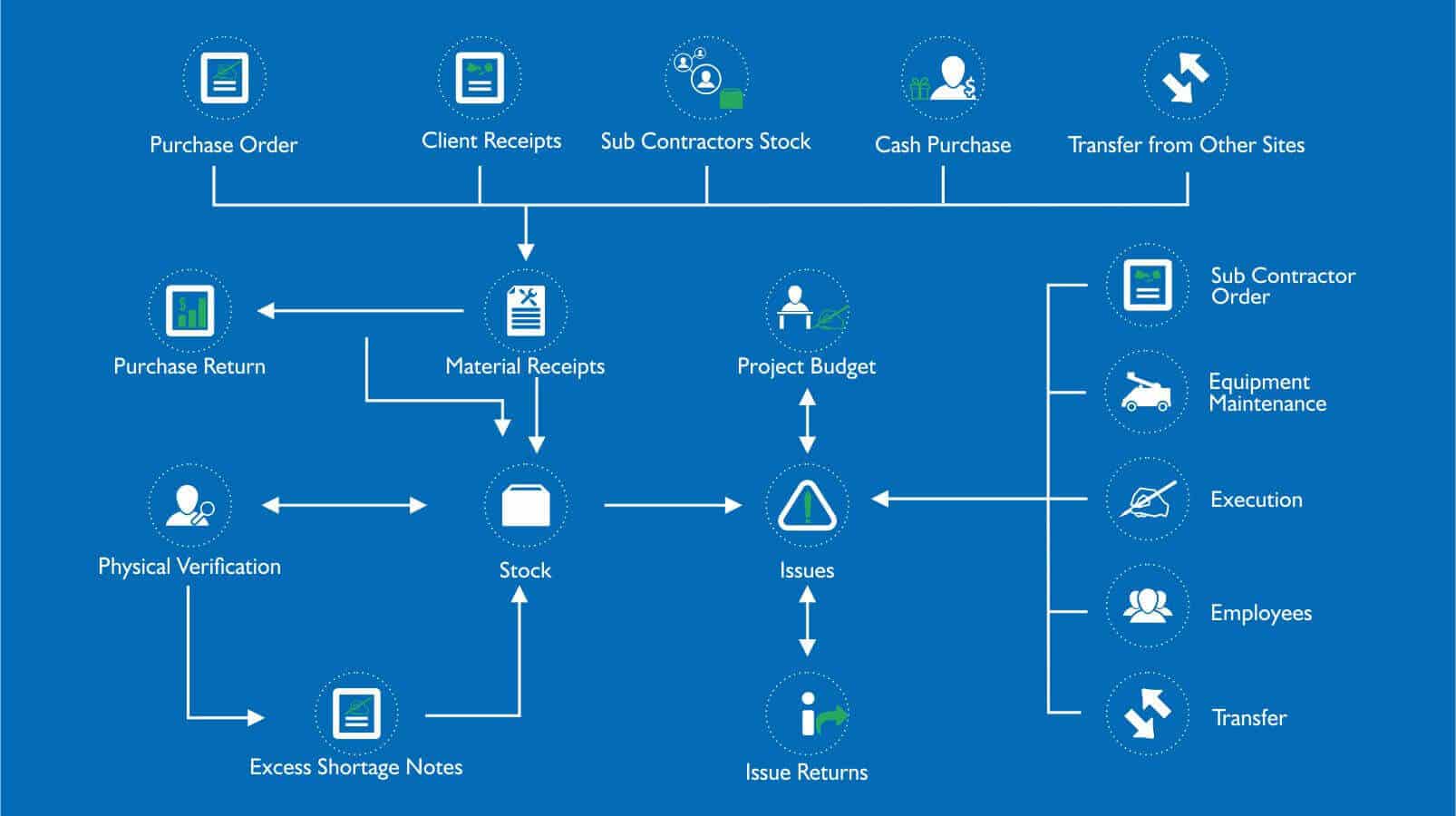

The Process:

The objective of an ERP system is to completely digitize the inventory system of the construction industry. This is first done by starting small at the process level. Once implemented, Tactive automates:

- Inter-site material transfer processes

- Trip sheet bookings for aggregates and standing purchase orders with split delivery

- Project-specific distribution of Material

- Debit accounting for pieceworkers & subcontractors for material supply

- The override approvals for project plan and emergency requirements

The Tactive Construction ERP software in its construction inventory module generates project-specific Stock Statements for finance submission, Ageing Analysis Report for reallocation, Material Reconciliation Report, Material Trend Analysis, etc., reducing the man-hours, errors, and prompts speedy execution of actions.

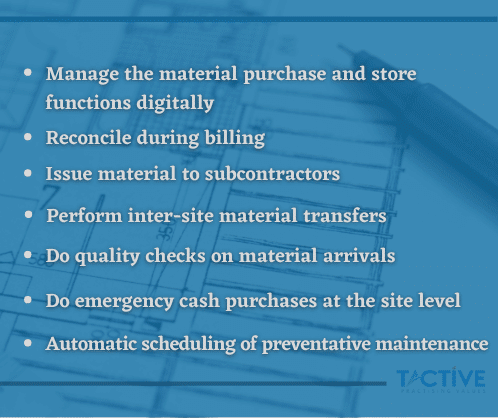

Long gone are the days when the processes, registry, logs, documentation were managed and monitored with pen and paper. With Tactive Construction ERP, you can now: Approve material deviation and appends, Issue long term fixed-rate contracts for materials or bulk purchases, Generate multiple delivery requests, Issue material from the site and stock them according to Cost code/work order/Employee, Record the logs for the Plant, digitally authorize the issue of spare parts for machinery, obtain receipts for materials delivered to the clients, Create Periodic stock audits at site and warehouse, and much more digitally to increase clarity and the overall productivity.

The Challenges:

Keeping track of materials, workforce, equipment, plant, etc, is important when a construction company has multiple projects to manage, as efficient scheduling can become very complicated. To simplify the otherwise arduous process, Tactive construction ERP (inventory module) allows the end-users to:

Inventory Management involves the integration of multiple activities and Tactive ERP material resource planner ensures the establishment of synergy among activities like:

- Resource evaluation.

- Lead time analysis.

- Supply and demand planning.

- Sourcing and procurement.

- Production planning and scheduling.

- Packaging and assembly.

- Inbound and outbound transport.

- Warehousing.

- Equipment/tools handling.

- On-site vehicle and plant management.

This enables the end-user to streamline the resources and obtain the optimal benefits from the existing resources on hand. In addition to keeping the construction program on-schedule, other advantages of the Tactive ERP Inventory Management Module include:

- Savings on cost and waste reduction to enhance productivity.

- Logistical planning on-site ensures the materials are stored in their appropriate locations.

- Sites are kept safe, clean, and easy to move around.

- Promptly receive, and efficiently handle deliveries.

Some of the many unique features that have been restructured by Tactive are discussed in detail…

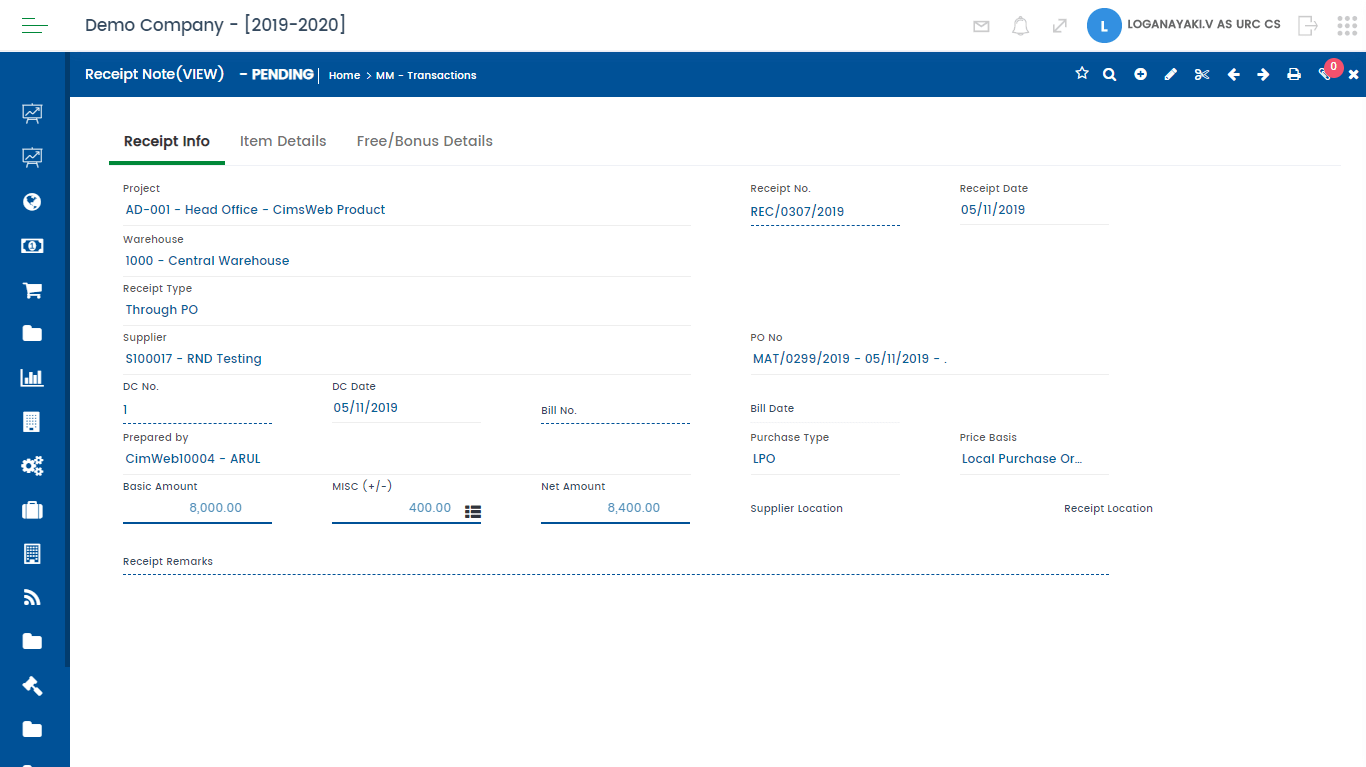

Receipt Note

MRN (Material Receipt Note) can be completely digitized to make a direct entry into the database right at the time of receiving the material. The details include:

- The project name,

- Date of receiving,

- Site location,

- Receipt type,

- Supplier,

- bill#, approval authority, etc.

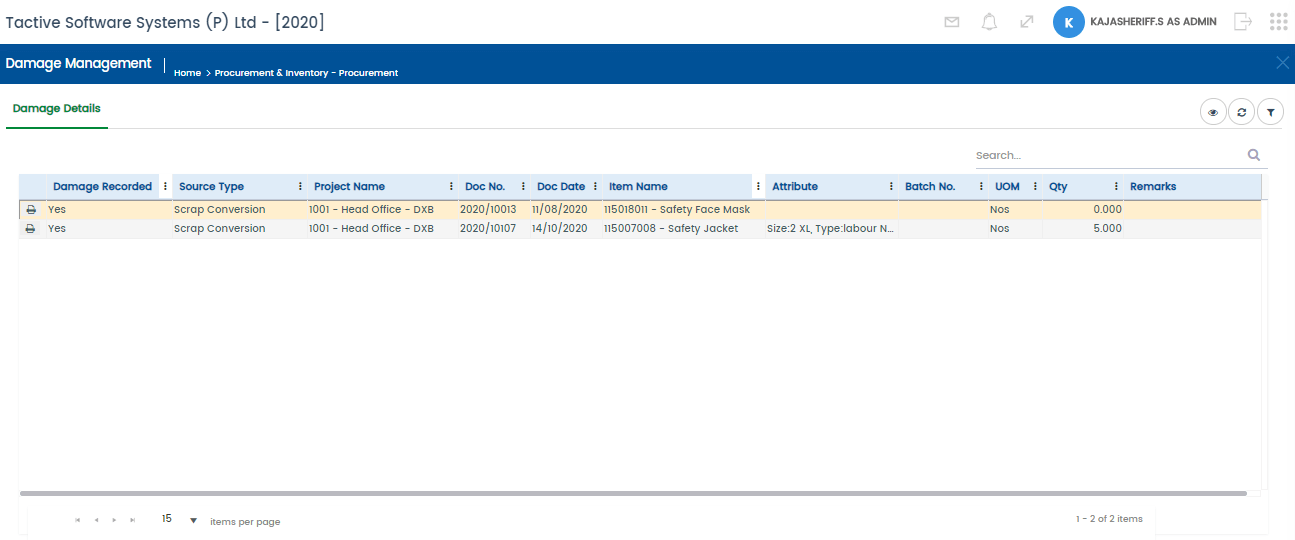

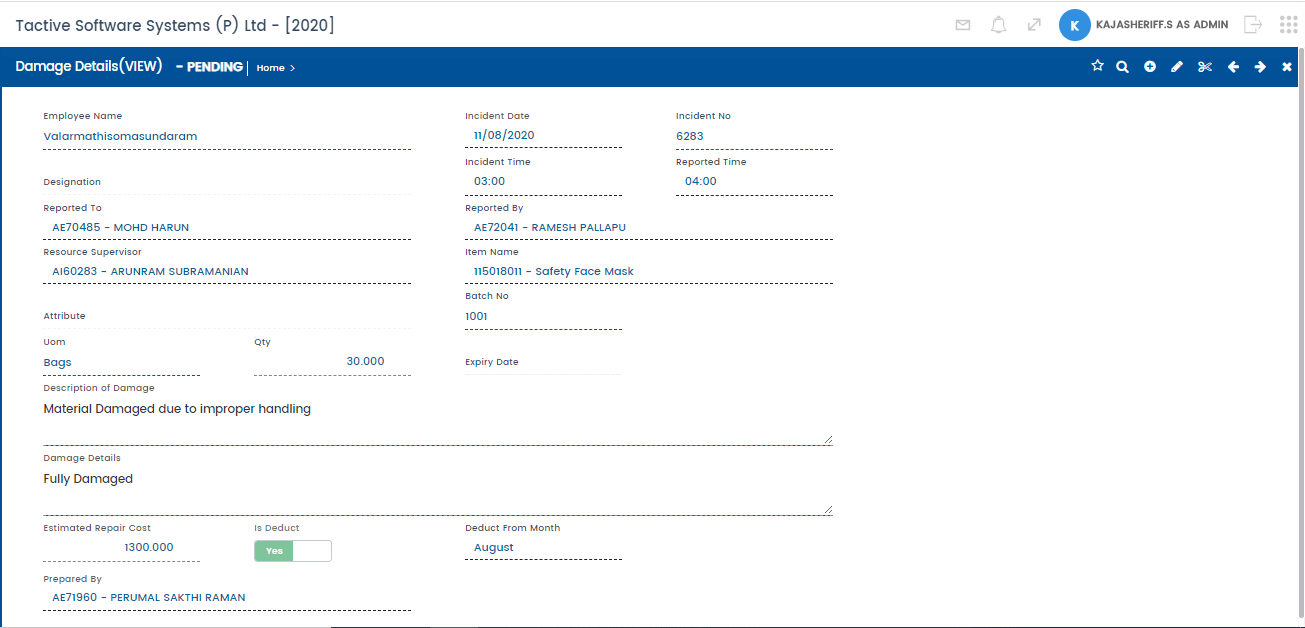

Damage Management

- Provision to record the damaged item details against the employee responsible

- Schedule and notify the salary deduction of the respective employee

- Option to view the details of damage in print format.

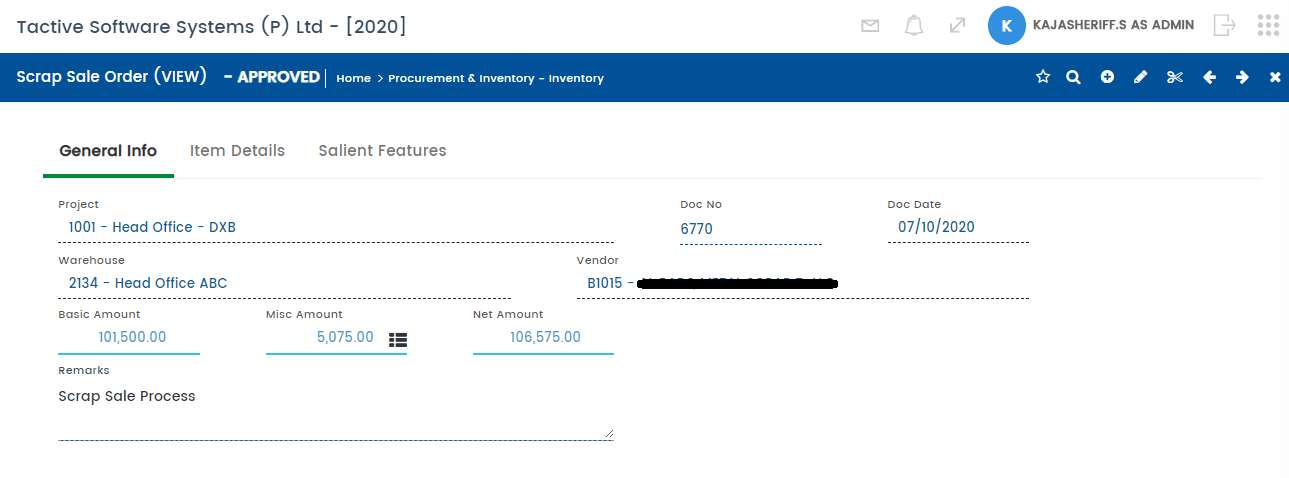

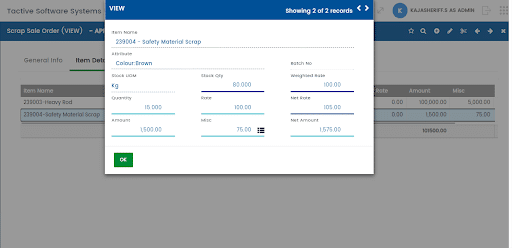

Scrap Sale Order

This is the process of making money from the dust. At the site level, the leftover materials can help make money if properly sold to a third party vendor or reutilized by the company at a different site (if there is a requirement). Scrap Sale Order by Tactive is raised digitally and systematically against the leftover tools, scraps, materials, etc that are in a fit condition for a third-party utilization. Provision will be given to:

- Sell the scrap material to customers and storing the receipt in a digital database

- Data will be loaded from the stock against the scrap material

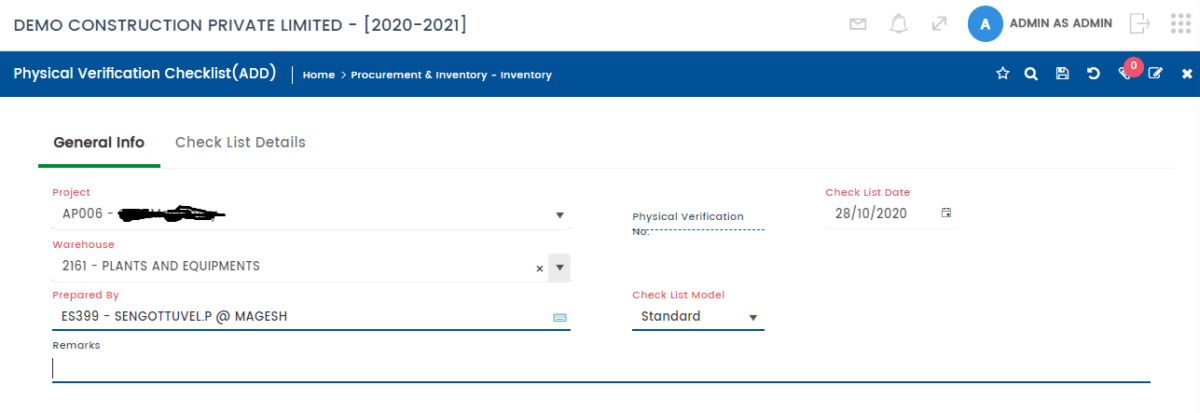

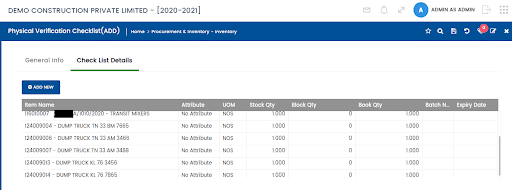

Physical Verification Checklist

The annually conducted activity is to make sure the stocks are in working condition and more importantly in their designated place in the expected quantity. Post evaluation, and cross-verification of the stock in the inventory, enter the data obtained into the PVC tab in the ERP to get the automated results of excess and shortage of goods and materials.

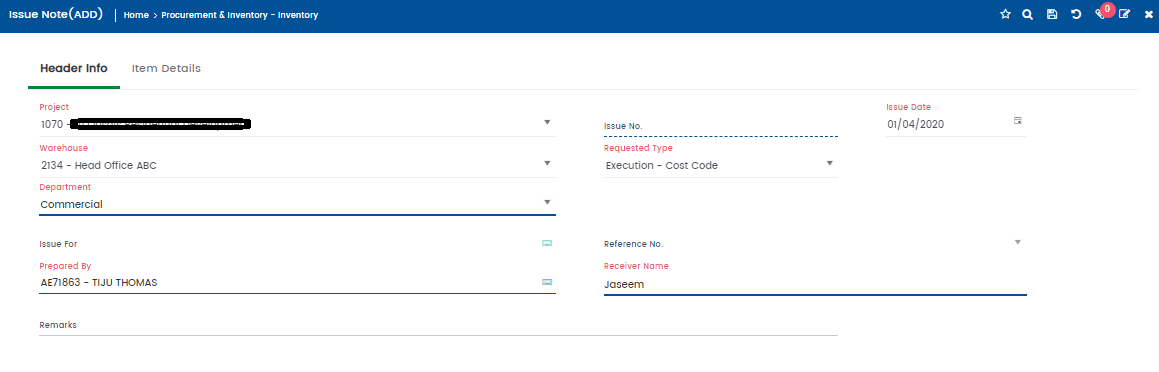

Material Issue and Return

Other peripheral areas of inventory management can not be ignored. Material Issue and Return is an essential activity that earns a few extra bucks for the company over some time. Tactive is built to overlook:

Issue and Purchase returns.

- Scope (budget) based material purchase indent.

- Vendor selection.

- RFQ, Quotations & Comparative statements, and many more…

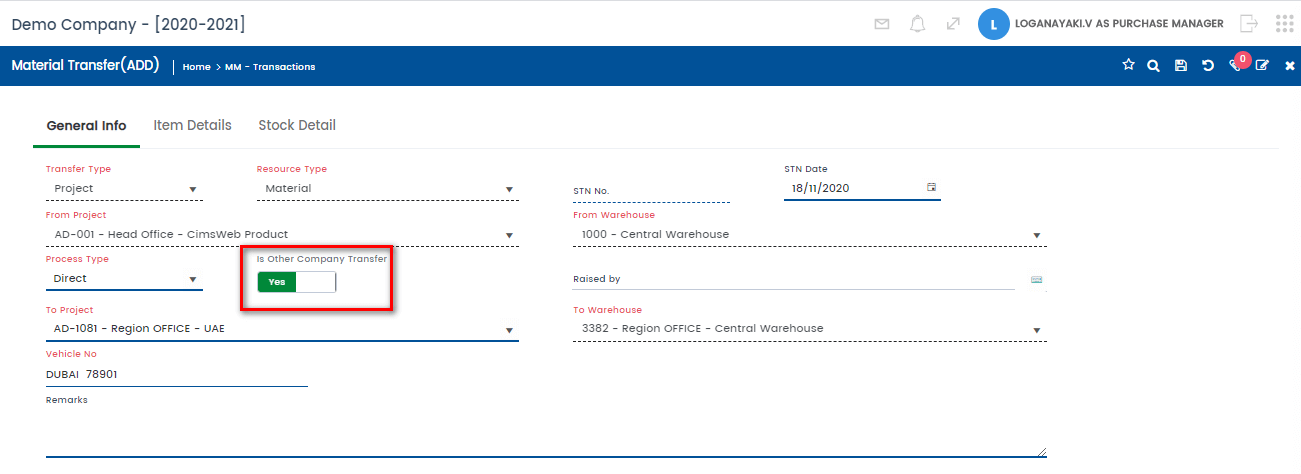

Other Company Transfer

Materials required for the immediate operations can be acquired from a different vendor operating under the same parent organization by raising a request order through the customized ERP portal. This saves more than 90% of the time taken if the operation is carried out via phone calls, in-person requests, etc.

The portal has been designed to give clarity on key aspects of the transfer like:

The type of transfer

- Type of Resource

- Process type

- Transfer location

- Vehicle details, etc

…end of the tour

Tactive has designed its Construction Inventory Module to help construction companies finish projects within budget and time. All the modules, eight so far, have been developed to work in tandem and provide a 360-degree digital fortress of a construction ERP solution to help customers build their dream.

The Inventory Module is one such innovation that seeks to integrate the resources, streamline and judiciously utilizing them for an effective outcome. Enabling our clients to seamlessly manage their resources has always been priority #1. For an up-close, real-time experience of Tactive ERP Solution, have a quick DEMO for free.

Issue and Purchase returns.

Issue and Purchase returns.  The type of transfer

The type of transfer