LMP stands for Labor, Machinery, and Plant. It’s a crucial segment of any construction activity. More than 75% of the overall allocated budget is being met by the LMP. One study found that proper utilization of manpower alone can help contractors save significant money by avoiding wastage and improper utilization of human resources. The plant and equipment/machinery consumes the highest in terms of maintenance charges.

Any effort put towards organising and standardizing the utilization of LMP can go a long way in saving the contractors to meet their long term goals of executing projects within schedule and budget. During the survey conducted by our team of experts, we found that the contractor was actively using the LMP but had little to no idea of how to improvise the usage of LMP.

This article is about the research conducted by Tactive in what are the challenges faced by its customers and what can be done to improvise the utility of LMP.

What’s the commonality with most of the contractors?

They hire men, buy machinery, and instal plants. This is it. No one has any idea about the hidden potential of these 3 crucial constituents of any construction activity. It looks like they are employing the LMP for the sake of it because their peers are known to do so.

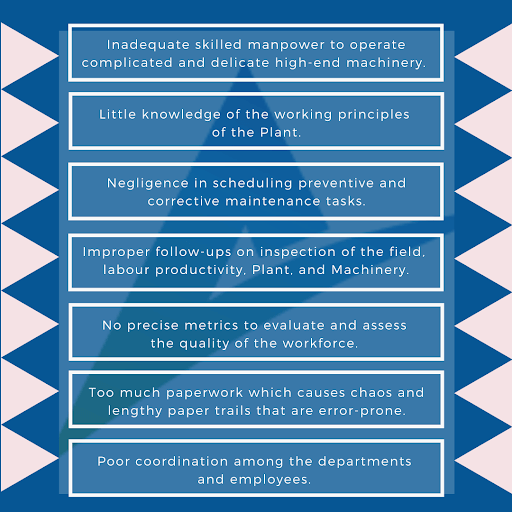

What are the problems faced by construction workers in terms of LMP?

Is there a loss of productivity due to these impediments?

The actual work done in a construction project is by the brown collared workers who are also the last man to actively use the machines and plants.

The labour charges are predominantly based on time and no. of working days. Lousy management of labours or delay in the execution of sub-tasks by the sub-contractors leads to the extended timeline which in turn incurs more cost.

In a similar context, breakdown in machinery and damaged plants can also cause delay and make the contractor spend more in the long run.

How can the challenges in effective utilization of LMP addresses?

A problem remains a problem so long as there is no real-time visibility, control, and understanding over that subject. What do we do to have a better understanding of the LMP? The answer lies in digitizing the entire organization from end-to-end to have a birds-eye view of all the operation and functionalities of the LMP.

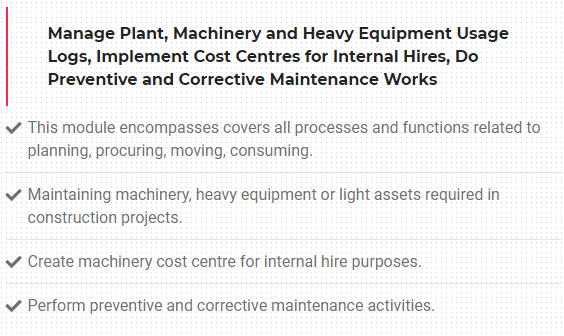

Digitization irons out the anomalies that prevent the LMP from having a smooth road-map. Eg: Using construction management software enables the project managers, site engineers, and other relevant personnel to effectively Manage:

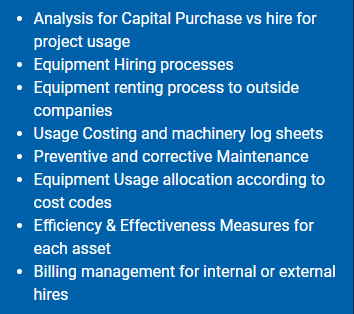

- Plant, Machinery, Heavy Equipment along with their respective Usage Logs,

- Implement Cost Centres for Internal Hires,

- Do Preventive and Corrective Maintenance Works,

- Track machinery and equipment movements,

- Lease/rent machinery to sub-contractors with real-time monitoring provisions,

- Auto reminded follow-ups on inspections, etc.

On top of this, the modern-day construction management software is capable of not just digitizing the process flow but also automating the same for speedy execution of tasks while saving cost, efforts, and errors.

What are the benefits of automating the LMP management process?

Each module is designed to capture the pain-points of a certain segment of construction, analyse it, and present the stakeholders with the precise data of what’s happening to enable the project managers to decide the future course of action.

Digitization helps in breaking down the complex structure of the construction workflow into smaller units to have high clarity. Automation makes it further easy to even monitor the digitized processes.

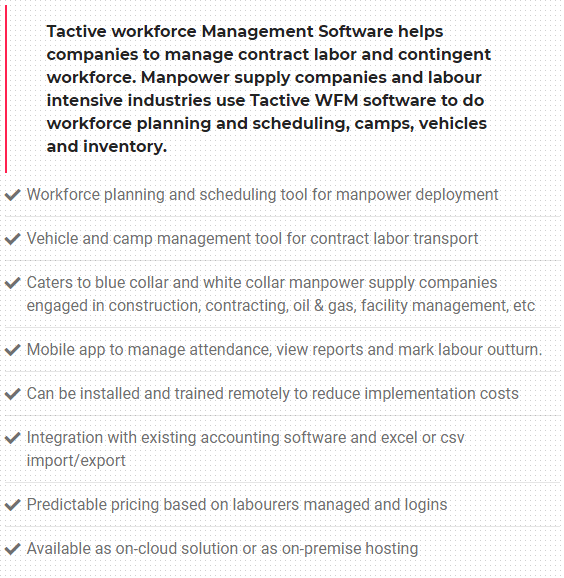

When it comes to managing the humongous labour workforce of a construction project, Regional planning heads, project managers, site engineers, etc can be benefited in the following ways:

The following are the reports that are auto-generated by the construction ERP software:

- Equipment Register

- Plant usage History and idle reports

- Replacement Analysis

- Usage/Labour Costs

- Maintenance reports (preventive & corrective)

- Plant/Material Transfer request and agreements

As these are auto-generated by the construction ERP s/w, it reduces the time taken for the preparation of these and also the man-made errors in calculation and other data entry processes.

Take a free DEMO of Construction ERP Software and know its potential in real-life construction scenarios.