Ensure zero downtime with smart equipment mobilization, usage, and maintenance.

Improve equipment performance and maximise the utilization of hire/own machinery

Define roles, IDs, standard running hours, fuel usage, and productivity benchmarks for each equipment.

Record daily running, worked, idle, and maintenance hours for each equipment with ease.

Track new and hire equipment receipts, returns, and project transfers with spares and checklists.

Track fuel usage and get alerts on overconsumption to control and reduce fuel costs.

Track, manage, and maintain all your equipment efficiently from mobilization to performance.

Schedule and track preventive or corrective maintenance with alerts, checklists, and job card requests.

Plan and allocate equipment with mobilization requests linked to budget, and project requirements.

Monitor underutilized equipment and improve usage efficiency across all projects.

Analyze equipment performance metrics to improve machinery efficiency and on-site productivity.

Availability vs Utilisation

Enhance efficiency in machinery with our construction equipment tracking software

Fuel Consumption

Analyse machinery fuel usage effectively with Tactive equipment maintenance software

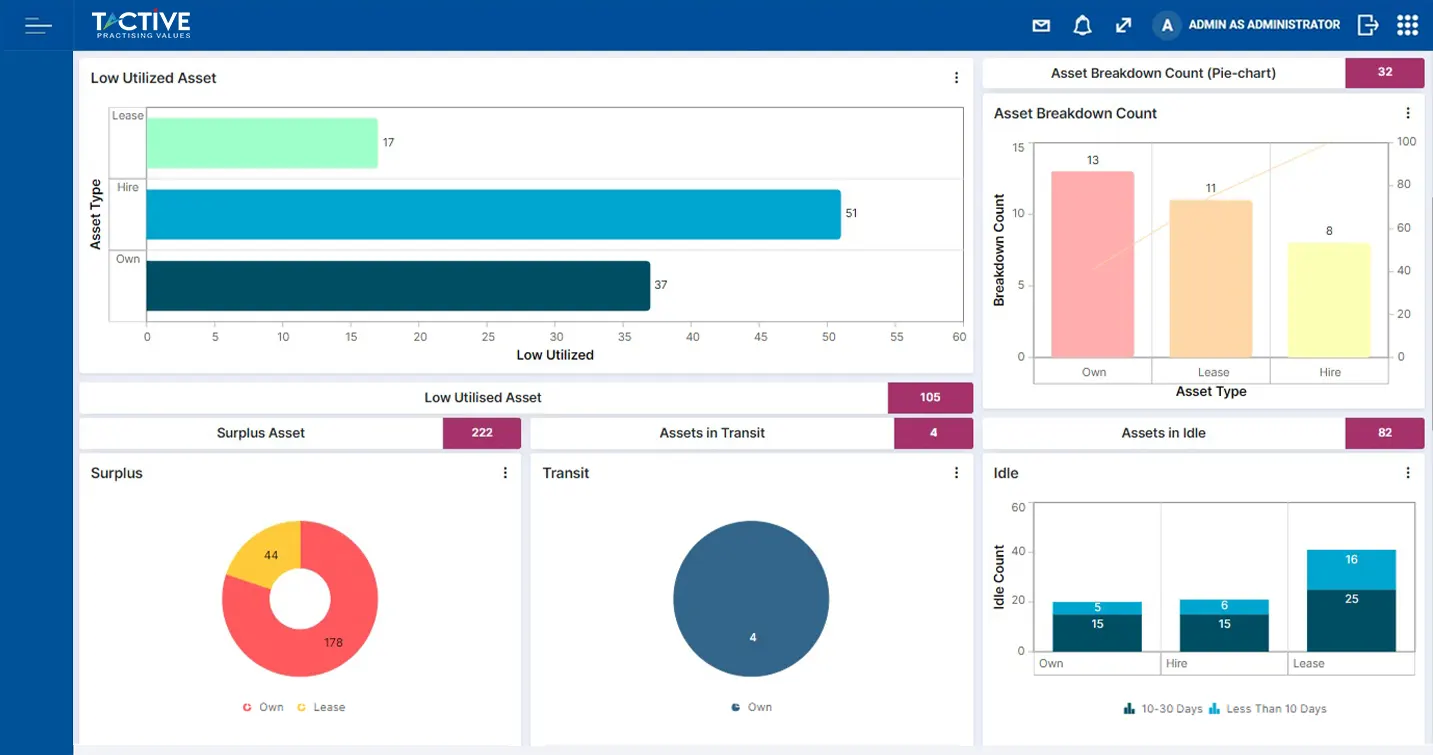

Asset Dashboard - Idle and Transit

Get the details of idle assets and breakdown status with our construction equipment software

Asset - Availability/Utilisation

Monitor the asset availability and utilisation with our construction equipment tracking software

With profound industry experience and expertise, the Tactive leadership sets valuable and realistic goals for the company

Get the option to capture equipment role, attributes, dimensions, and component details and define the Automatic Equipment ID based on self-configuration.

The Tactive construction management system helps to capture equipment usage log, transfers, fuel consumption, productivity of individual equipment, and the spare details against individual equipment as per the manufacturer’s specifications, preventative and corrective maintenance.

Yes, the usage log option helps to Capture individual equipment-wise running hours, idle hours, break-down hours on a daily basis.

To save on equipment rental costs, we can move surplus or unused equipment to the project that requires it, by using the allocation process. Additionally, for any hired equipment that is not being utilised, can be tracked using the usage log. This approach ensures a more efficient use of hired equipment.

Fuel Efficiency Report, Availability vs Utilisation, Asset profile, daily log sheet report, monthly performance report, asset surplus or idle analysis, asset movement history report, maintenance history report, job card report are few of the reports which can be generated with Tactive construction ERP software.

Budget controlled mobilisation request, Control on Overconsumption, Tracking and Monitoring of Idle and Running Machineries, transferring it within and other projects, Machinery maintenance, are the few benefits of Tactive equipment management system.

Yes. Secured integration is possible with all other softwares.

Yes, the Tactive system enables you to make maintenance schedules on a calendar basis monthly or yearly, and the system gives a prompt alert while nearing the due date.

The Tactive construction ERP software enables preventive and corrective maintenance of the machinery.

The Tactive construction ERP software allows efficient management of both owned and hired vehicles.

Yes, Tactive machinery management software helps to compare the hire quotation and order from different suppliers and enables to choose the vendor with the best price.

Yes, the mobile application of Tactive construction management software helps to enter the usage log of the equipment making it easy for the staff working on-site. And has provision for the management team to view dashboards with all relevant information, for quick decision making.

Yes, Tactive construction ERP software has the budget control option for equipment, and enables equipment wise control over the usage.

Yes, the Tactive construction ERP software has the equipment management dashboard that displays the total no.of asset deployed, utilisation, low utilised assets etc. The software also enables the customer to change the dashboard view according to their requirement.